The 50kW On-off Grid Controller with Pitch Controller represents a sophisticated integration of renewable energy management and wind turbine optimization, engineered for medium-scale hybrid power systems.

| Availability: | |

|---|---|

| Quantity: | |

Type | NE-GT15KW | ||

Wind turbine rated power | 15KW | ||

Wind turbine Max. power | 30KW | ||

Wind turbine rated voltage | AC380V-400V | ||

Function | Rectifier,control, DC output | ||

Automatic protection function | Over voltage protection, network electric cut off protection, regulated supply output, arrester, reset, emergency switch, Yaw control, change OARS | ||

Manual function | Manual brake | ||

Display mode | LCD | ||

| Display content | Wind turbine voltage, current, power; Solar voltage, current, power; DC output voltage, DC output current, DC output power, total power. | ||

PWM constant voltage | ≥550dc | ≥550dc | ≥550dc |

Wind turbine deflection 45°(adjustable) | ≥550dc | ≥550dc | ≥550dc |

Wind turbine 3-phase dump load voltage1 | 580±5Vdc | 580±5Vdc | 580±5Vdc |

| Wind turbine 3-phase dump load voltage2 | 580±5Vdc | 580±5Vdc | |

Wind turbine deflection 90°(adjustable) | 580±5Vdc | 580±5Vdc | 580±5Vdc |

Time-lapse of the wind turbine 3-phase dump load2 | 12-20 min | 12-20 min | 12-20 min |

PWM dump load fuse | 50A | 63A | 80A |

Fuse of DC output | 63A | 80A | 100A |

Wind speed adjustable) | ≥2m/s | ||

| Wind direction adjustable) | 0-360° | ||

Work environment temperature | -30-60°C | ||

Relative humidity | <90% No condensation | ||

Noise (1m) | <40dB | ||

Degree of protection | IP20(Indoor) IP65 (Outdoors) | ||

| Cooling method | Forced air cooling | ||

*Communication interface (optional) | RS485/USB/GPRS/WIFI/Ethernet | ||

*Temperature compensation(optional) | -4mv/°C/2V,-35°C~+80°C,Accuracy:±1°C | ||

Size of the controller (mm) | 600*550*1220mm | ||

Weight of the controller | 80KG | ||

Size of the dump load (mm) | 690*450*530 | 720*500*1300 | 720*500*1300 |

| Weight of the dump load | 41Kg | 70Kg | 80Kg |

*Above parameter only for reference

1. Could be custom made to user specifications.

2. Could have solar power control subject to user demand.

Type | NE-GT50KW | NE-GT100KW | NE-GT200KW |

Wind turbine rated power | 50KW | 100KW | 200KW |

Wind turbine Max. power | 100KW | 200KW | 300KW |

| Wind turbine rated voltage | AC380V-400V | AC380V-400V | AC380V-400V |

Function | Rectifier,control, DC output | ||

Automatic protection function | Over voltage protection, network electric cut off protection, regulated supply output, arrester | ||

Manual function | Manual brake, reset, emergency switch,Yaw control, change OARS | ||

Display mode | LCD | ||

| Display content | Wind turbine voltage, current, power; Solar voltage, current, power; DC output voltage, DC output current, DC output power, total power. | ||

PWM constant voltage1 | ≥550dc | ≥550dc | ≥560Vdc |

PWM constant voltage2 | ≥550dc | ≥560Vdc | |

Wind turbine deflection 45°(adjustable) | ≥550dc | ≥550dc | ≥560Vdc |

Wind turbine 3-phase dump load voltage1 | 575±5Vdc | 575±5Vdc | 580±5Vdc |

Wind turbine 3-phase dump load voltage2 | 580±5Vdc | 580±5Vdc | 12-20 min |

| Wind turbine 3-phase dump load voltage3 | 580±5Vdc | 600±5Vdc | |

Wind turbine deflection 90°(adjustable) | 580±5Vdc | 580±5Vdc | 12-20 min |

Time-lapse of the wind turbine 3-phase dump load2 | 12-20 min | 12-20 min | 600±5Vdc |

PWM dump load fuse | 63A | 80A | 12-20 min |

Fuse of DC output | 80A | 100A | 63A*3 |

Wind speed(adjustable) | ≥2m/s | ||

| Wind direction(adjustable) | 0-360° | ||

Work environment temperature | -30-60°C | ||

Relative humidity | <90% No condensation | ||

Noise (1m) | <40dB | ||

Degree of protection | IP20(Indoor) IP65 (Outdoors) | ||

| Cooling method | Forced air cooling | ||

*Communication interface (optional) | RS485/USB/GPRS/WIFI/Ethernet | ||

*Temperature compensation(optional) | -4mv/°C/2V,-35°C~+80°C,Accuracy:±1°C | ||

Size of the controller (mm) | 600*500*1200mm | 600*500*1200mm | 600*500*1200mm |

Weight of the controller | 94Kg | 96Kg | 96Kg |

Size of the dump load (mm) | 720*500*1300 | 720*500*1300(2pcs) | 720*500*1300(2pcs) |

| Weight of the dump load | 107Kg | 107Kg*2 | 107Kg*2 |

*Above parameter only for reference

1. Could be custom made to user specifications.

2. Could have solar power control subject to user demand.

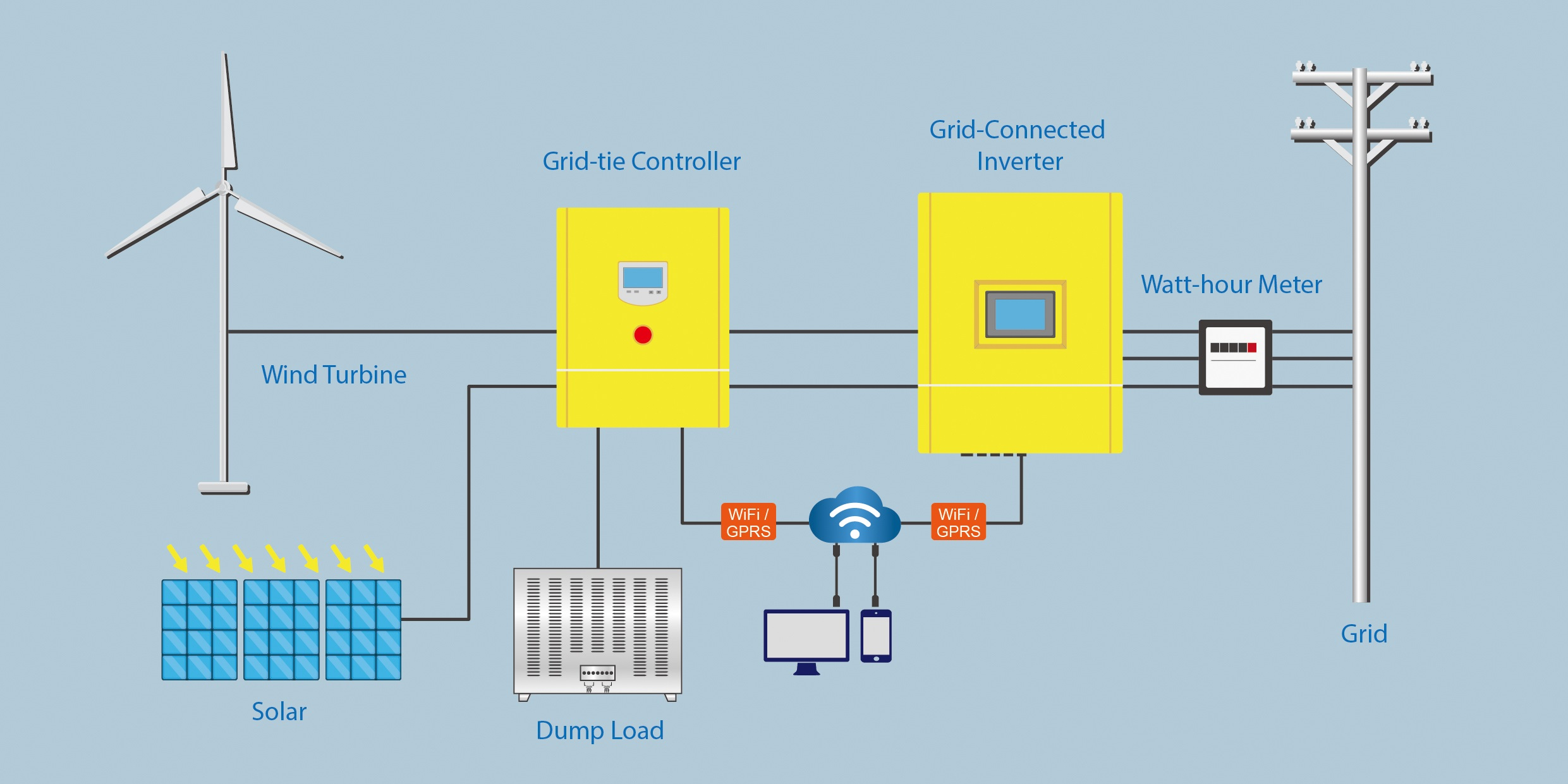

This dual-mode controller seamlessly switches between grid-connected and off-grid operation while regulating wind turbine performance through its integrated pitch control system. Certified to EN ISO 13849-1 Performance Level d (PLd), the pitch controller ensures safe rotor blade adjustment during varying wind conditions, preventing over-speed situations and maximizing energy capture . With a power handling capacity of 50kW, it accommodates both solar PV arrays and wind turbines, making it ideal for remote communities, industrial facilities, and off-grid power stations requiring reliable renewable energy integration.

The controller intelligently balances power input from solar and wind sources, prioritizing renewable generation while drawing from the grid or backup systems when necessary. Its advanced algorithm optimizes energy flow to maintain stable voltage and frequency, ensuring uninterrupted power supply in both on-grid and off-grid modes.

Equipped with a 3-phase, 400V AC pitch drive system operating within the 18kW to 42kW range, the controller adjusts rotor blade angles in real-time based on wind speed and system demand . This not only protects the turbine from damage during high winds but also increases annual energy production by up to 15% through optimal blade positioning.

Featuring dual anti-islanding protection mechanisms compliant with UL 1741 standards, the controller disconnects from the grid within 2 seconds during faults . Redundant power supplies and fail-safe brakes ensure the pitch system operates independently even if the main control unit malfunctions, achieving the highest safety level for wind turbine operation .

Integrated Profinet and EtherCAT interfaces enable seamless communication with SCADA systems and remote monitoring platforms . Users can track real-time performance metrics, including energy production, pitch angle positions, and system health, facilitating predictive maintenance and performance optimization.

Mining operations, construction camps, and telecommunication towers in off-grid locations utilize this controller to combine wind and solar power, reducing diesel generator dependency and operational costs. The pitch control feature ensures consistent energy output despite fluctuating wind conditions.

Isolated communities with limited grid access benefit from the hybrid functionality, using renewable energy for base load requirement while relying on the grid or backup generators during peak periods. The system supports gradual energy independence as renewable capacity expands.

Medium-scale renewable energy projects integrate multiple wind turbines and solar arrays under this controller’s management, achieving higher capacity factors through complementary generation profiles. The pitch controller maximizes wind energy harvest without compromising turbine safety.

The pitch controller adjusts rotor blade angles to reduce wind capture during high-speed conditions, preventing dangerous over-speeding. It achieves PLd safety level under EN ISO 13849-1, ensuring independent safety runs even during control system failures .

Yes, the controller supports full off-grid operation when paired with appropriate energy storage systems. It manages battery charging/discharging cycles while coordinating with the pitch controller to maintain system stability without grid support.

The controller features Profinet, EtherCAT, CANopen, and Powerlink interfaces, enabling integration with various industrial monitoring systems and SCADA platforms for centralized management .

When combined with properly sized turbines, the pitch controller adjusts blades to feather position during extreme winds exceeding 25m/s (90km/h), protecting the turbine from structural damage while maintaining system integrity.

NE-GT (Grid-tie) model On grid Wind Turbine Controller Product Characteristics

1.The product is manufactured according the JB/T6939.1-2004 industrial standard and GB/T 19115.1-2003 national standard also with users’ technical requirements.

2.Big LCD display.The images tell working state visually.Various data show: real-time wind turbine voltage,current,solar panel voltage,current,DC output voltage,current,total power generation(The main board is with button battery,in case of power failure, history data can be saved for 30 days).

3.Two sets of control systems:PWM constant voltage system and three-phase dump load system.

4.PWM constant voltage control is 120% of the rated power of the wind turbine. In case exceeding of PWM’s capacity, the three-phase dump load will automatically start immediately. After 10-20 minutes, the three-phase dump load will stop and the wind turbine will re-start to resume power supply to ensure the safe running of the overall wind turbine generation system.

5.When the strong or super-strong wind conditions, the controller can conduct constant voltage output to ensure the inverter safety running.

6.When the condition of disconnected grid-connected inverter, the controller can conduct constant voltage output and wait for inverter resumption.

7.When the grid is cut off, the three-phase dump load of the controller will automatically start to work and the inverter will stop output to grid. When the grid resuming, the controller stops three-phase dump load and the inverter will resume power supply.

8.The inside of the controller is equipped with surge protector. Contain the over voltage into the wind turbine under the bearable voltage of the equipment or system. On another way, to conduct the strong lightening current into the earth directly to avoid any damage of equipment.

9.The controller is equipped with emergency stop switch; in case of emergency, press down the emergency stop button in the front panel to cut off all power supply of the controller and the wind turbine will immediately brake(three-phase dump load).

10.The controller is equipped with manual three-phase dump load switch. To using this switch, the wind turbine will brake (three-phase dump load).

※ Adopt Modbus Communication protocol. Convenient to carry out the secondary development.

※ Adjusting the technical specification via RS485 is available.Convenient to adjust the different wind turbines for professional customers.

※ Support WIFI and GPRS.Customers can monitor the real-time working state of the on grid wind power system via PC and mobile and query history working sate.Both Android and OS are compatible in Mobile.

※ Can increase the solar panel control system according to customer requirements.

※ For the different wind turbine, the controller can be equipped with mechanical yawing, rotate tail control, furled empennage, mechanical brake,hydraulic brake, electromagnetism brake and other brake functions.

On Grid Wind Turbine Controller 50KW-200KW

Product photo

|

|

Technical Parameters